Check out our blog to learn why the right partner can make a difference for cementing operations.

Read BlogWe’ve been a family-owned and operated business since 1970. See why we’ve been the leader in oil field services for more than 50 years.

Read BlogPlug and Abandonment is an essential process in the oil and gas industry to permanently seal non-producing wells, mitigate environmental risks, ensure safety, comply with regulations, and manage assets effectively.

P&G offers a wide range of capabilities to serve a diverse set of plug and abandonment requirements in the region. Exploration companies and state governments are suffering the same ailment: how to plug wells quickly, safely and inexpensively.

The expertise and tools required for plug and abandonment of conventional wells are drastically different from those required for first-generation shale gas wells that now require decommissioning. The contractor market remains fragmented and likewise unable to meet demand cost-effectively. Most significantly, pressure to plug more wells for less money has created a culture of shortcuts and unsafe work practices.

This is why P&G is the contractor of choice for dozens of clients undertaking plug and abandonment projects.

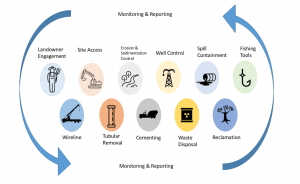

P&G’s solution to many of the problems facing clients lies in its turnkey model of plug and abandonment project management. Hidden costs are eliminated by setting a not-to-exceed ceiling. The project is managed more efficiently as subcontractor use is minimized or eliminated.

Start-to-finish project oversight allows information to be freely shared from one responsible party to the next. By combining all this with a culture of safety and environmental stewardship, we solve the most difficult problems facing clients in the United States today.

Listed below are a handful of P&G’s capabilities that allow us to thrive in this segment:

“Plug and Abandonment” refers to the process of permanently sealing an oil or gas well that is no longer productive or economically viable. When a well reaches the end of its operational life, or if it becomes unsafe or uneconomical to continue production, it needs to be properly closed off to prevent any potential environmental or safety hazards.

The Plug and Abandonment process typically involves several steps, including the retrieval of production equipment from the well, removal of wellhead and associated infrastructure, and the placement of cement plugs at various depths within the wellbore to isolate and seal off different zones. The well is then capped with a permanent seal or a device called a wellhead plug to prevent the migration of fluids or gases between different geological formations.

The importance of Plug and Abandonment in the oil and gas industry can be attributed to several reasons:

Properly plugging and abandoning wells is crucial for safeguarding the environment. Abandoned wells that are not sealed can potentially leak hydrocarbons, brine water or other harmful substances into groundwater or surface water, leading to contamination and ecological damage. By conducting effective Plug and Abandonment operations, the industry aims to minimize the risk of such incidents and protect the environment.

Abandoned wells that are not properly plugged can pose safety risks, such as the uncontrolled release of hydrocarbons or the potential for blowouts. These situations can result in explosions, fires and other hazards. By performing Plug and Abandonment activities, the industry mitigates these risks and ensures the safety of workers, nearby communities and infrastructure.

Governments and regulatory agencies impose strict regulations and guidelines regarding the abandonment of wells. Oil and gas companies are required to adhere to these regulations to maintain compliance and avoid legal consequences or penalties. By conducting Plug and Abandonment operations in accordance with the regulatory framework, companies demonstrate their commitment to responsible resource extraction and environmental stewardship.

Plug and Abandonment is a critical component of the overall lifecycle management of oil and gas assets. By properly plugging and abandoning non-producing wells, companies can retire unproductive assets and allocate resources more efficiently. This process also involves estimating and setting aside financial provisions for future Plug and Abandonment activities, ensuring that the costs associated with decommissioning and environmental remediation are adequately covered.

Learn all the ins and outs in this on-demand Plants & Goodwin webinar.

Timely Plug and Abandonment despite challenging downhole conditions enabled customer to develop adjacent wells.

View ProjectRecognizing outdated service equipment’s capability maximizes well customer’s benefit.

View ProjectPlug and Abandonment cost on long-neglected, legacy well undercuts allocated budget by 30%.

View ProjectPlug and Abandonment on well in Ohio lakebed ends environmental threat in one week.

View ProjectAbandoned oil and gas wells that have not been sealed securely can pose a variety of environmental and health hazards. Degrading cement and steel that compose wellbores can lead to migration of gases or fluids, which can contaminate surface water or groundwater, and in some cases, accumulations of gases can lead to explosion risks. These hazards become more likely if unsealed wells are near oil and gas enhancement operations utilizing hydraulic fracturing. Unsecured wells may also pose a danger to human health through emissions of air pollutants such as benzene, hydrogen sulfide or volatile organic compounds (VOC).

When decommissioning oil and gas wells, there are several steps involved. First, the condition of the well is assessed, including the underground casing and cement, to identify any leaks or dangers below the surface. Then, the wellbore is cleaned and sealed using cement or other materials. The extent of sealing depends on the conditions underground and regulatory requirements. Finally, the equipment on the surface is taken away, and the area around the well is restored following reclamation standards.

The cost of Plug and Abandonment operations depends on key factors and well characteristics: well type (oil or gas), age, depth, complexity (laterals and number of completions), location and regulatory requirements. In 2021, an industry research group put the median cost for decommissioning a well in the U.S. at approximately $20,000 for plugging and $76,000 for plugging and surface reclamation. They further found that for each additional 1,000 feet of well depth, the cost increased by 20%, and that older wells are more costly than newer ones. Natural gas wells are 9% more expensive than oil wells, with costs varying widely by state. Research also found that surface characteristics around the well substantially affect operational costs. Each additional 10 feet of elevation in a 5-acre area surrounding wells raises costs by 3%. On the plus side, this research also showed that operators who arranged contracts with services companies to perform Plug and Abandonment operations on collective assets reduced their decommissioning costs by 3% per well.

According to the Code of Federal Regulations under Title 30, lessees, owners of operating rights, and their predecessors are jointly and severally liable for meeting decommissioning obligations for facilities on leases, including the obligations related to lease-term pipelines, as the obligations accrue and until each obligation is met. To further clarify this part of Title 30, lessees and the owners of operating rights include two stakeholders: those that have paid for the right to develop oil and gas wellsites and those operators who have drilled and completed wells. And, because these parties are subject to change, decommissioning obligations can revert in part to a party or parties that held interest in a well prior to those who currently hold or were the last to hold interest in a well.

Abandoned wells are a danger to health because they can contaminate groundwater, making the water unsafe to drink. This contamination includes harmful substances like benzene, which can cause diseases like aplastic anemia and leukemia. Additionally, these wells release methane, a potent greenhouse gas approximately 25-84 times more effective at trapping heat in the atmosphere than carbon dioxide over a 20-year period. The large-scale emission of methane from abandoned wells poses a serious threat to our climate and sustainable economic growth. When oil and gas wells are not correctly closed down, they keep releasing methane into the air and pollute the groundwater that local communities depend on for clean drinking water.

The process of permanently sealing an oil or gas well, also known as well plugging, that is no longer productive or economically viable. It involves isolating and sealing different zones within the wellbore using cement plugs to prevent fluid migration and potential environmental hazards.

Also known as fracking, it is a well simulation technique in which high-pressure fluids are injected into a reservoir to create fractures in the rock formation, allowing for better oil or gas flow.

A safety device installed at the wellhead to control and prevent the uncontrolled release of hydrocarbons during drilling, completion and well plugging operations.

Gases, including methane and carbon dioxide, that trap heat in the Earth’s atmosphere and contribute to global warming and climate change.

The release of methane gas into the atmosphere, often associated with the extraction and production of oil and gas. Methane is a potent greenhouse gas that contributes to climate change. These emissions are particularly relevant during gas and oil well abandonment, a phase of well decommissioning when wells that are no longer productive or safe to operate are permanently sealed. Proper sealing during gas and oil well abandonment is essential to prevent the uncontrolled release of methane into the atmosphere, mitigating its impact on global warming and climate change.

The condition of the well’s casing, which is the steel pipe lining the wellbore. Proper casing integrity is essential to prevent fluid migration and maintain well stability.

The process of restoring the land around an abandoned well to its original condition or an environmentally safe and stable state.

Abandoned oil or gas wells for which there is no responsible party to plug and remediate. Orphaned wells often become a burden on state governments and local communities.

The process of ceasing operations and closing down an oil or gas well that is no longer economically viable or safe to operate.

A project management approach in which a single contractor takes responsibility for the entire project, from start to finish, eliminating the need for multiple subcontractors.

The pollution of underground water sources, such as aquifers, by harmful substances including hydrocarbons, chemicals or brine water, often resulting from poorly abandoned wells.

A measure of how much a greenhouse gas, such as methane, can contribute to global warming over a specific time period compared to carbon dioxide.

The movement of gas, including methane, through subsurface formations or wellbores, which can lead to environmental and safety issues if not controlled.

The process of performing various operations in a well to maintain or enhance its productivity, including well plugging, for wells that are no longer productive or need to be safely closed. Well intervention services may also involve other activities such as hydraulic fracturing or well stimulation techniques to improve oil or gas flow.

A barrier placed within an oil wellbore to permanently seal off specific zones or the entire well when it is no longer productive or economically viable. The process of installing an oil well plug, known as well plugging or plug and abandonment, involves pumping cement or other sealing materials into the wellbore to prevent the migration of fluids between different geological formations. Properly installed oil well plugs ensure environmental protection, safety and compliance with regulatory requirements after the cessation of oil production or when the well poses potential hazards.

A comprehensive range of specialized operations and techniques performed in an oil or gas well to optimize its productivity, integrity and safety. Well intervention services are carried out throughout the lifecycle of the well, addressing various challenges such as maintenance, production enhancement, well control and well abandonment.

Get in touch with Plants & Goodwin today.

CONTACT US